Journal of Sol-Gel Science and Technology - Micrograph of the Month

Introducing Micrograph of the Month! To highlight our authors and their works, each month we'll feature an interesting and visually striking micrograph (or series of micrographs) chosen from a recent issue of the Journal of Sol-Gel Science and Technology or from unpublished sources such as PhD theses, etc (with full attribution given). If you know of any interesting images that might be suitable, please contact the ISGS Newsletter Editor (this opens in a new tab) for inclusion. The micrographs can be optical, SEM, TEM, AFM, etc, and a brief description of the samples should be provided.

Also, check out ISGS Newsletter's sister highlight program, Molecule of the Month! (this opens in a new tab)

October, November, and December 2023

This months’ images are taken from four different papers in the latest issues of JSST and once again highlight the breadth of sol-gel science and technology, together with the areas in which our community is making an impact.

The first micrographs are taken from the work of Wang, Long Su, Jiang Zheng, Yang, Li and Zou entitled “Study on preparation of SiO2/PTFE aerogel-like materials via atmospheric drying and their thermal insulation performance” ((JSST (2024) 109, 204-214; https://doi.org/10.1007/s10971-023-06261-0 (this opens in a new tab)). This work explores the synthesis and characterisation of hybrid SiO2/PTFE aerogels with densities as low as 0.087 g/cm3 obtained via a low -temperature ambient pressure drying strategy. As illustrated in the left-hand photograph, the materials exhibit excellent mechanical properties, with essentially no thermal decomposition at temperatures below 500oC. They remained hydrophobic even after exposure to 1 M HCl for one week, with contact angles of 140o being observed (middle photograph). The thermal conductivity of the optimum material was ~ 64 mW/mK, which is slightly higher than that of similar aerogel materials prepared from precursors such as MTMS. However, as illustrated in the right-hand photograph, the SiO2/PTFE aerogel still exhibits excellent thermal insulation properties.

The second series of micrographs is from the work of Yan, Liang, Liu, Zhang, Zeng, Bai, Zhu and Li. This paper, entitled “Synthesis of PANI@α-Fe2O3/Al2O3 photo-Fenton composite for the enhanced efficient methylene blue removal” (JSST, (2024) 109, 137-149; https://doi.org/10.1007/s10971-023-06253-0 (this opens in a new tab)), explores the hydrothermalassisted sol-gel synthesis of nanocomposite photocatalysts based on Fe2O3 supported on flat α-Al2O3 plates. Following heat-treatment at selected temperatures, the Fe2O3/Al2O3 plates were coated with polyaniline and used as anodes in an electric-field-assisted photo-Fenton reactor. At processing temperatures under 500oC, the Fe2O3 formed nanorods on the surface of the Al2O3 plates, with the width and length of the rods increasing with temperature. At 550oC, α-Fe3O3 nanotubes were formed. Under optimal conditions, up to 98 % decomposition of methylene blue dyes were obtained in the electric-field-assisted reactor over a wide pH range (pH 4-9).

The third series of images is from the work of Li, Xu, Xu, Zhu, Wang, Jiang and Jin entitled “Universal and facile sol-gel approach for fabrication of multitudinous yolk-shell architectures” (JSST, (2024) 109, 421-432; https://doi.org/10.1007/s10971-023-06289-2 (this opens in a new tab)). This paper explores the synthesis and optical properties of hollow yolkshell architectures consisting of mesoporous silica shells containing “yolks” consisting of species such as PtOx, IrOx, FeOx and titanosilicate zeolites. An example of the intriguing morphologies obtained is shown in the micrographs below, which illustrate the structure of particles with an IrOx yolk and a mesoporous silica shell.

The final series of images is from the work of Peng, Liu, Zeng, Cui, Wang, Li, Liu, Wang and Liu. This paper, entitled “Low temperature deep eutectic solvents-assisted synthesis of amorphous MnO2 cathode for zinc ion batteries” (JSST, (2024) 109, 695-706; https://doi.org/10.1007/s10971-023-06308-2 (this opens in a new tab)), describes the synthesis and characterisation of cathode materials for zinc ion batteries. The cathode material was synthesised in a deep eutectic solvent consisting of urea and betaine, from which MnO2 was produced via the ambient-temperature reduction of KMnO4. The micrographs illustrate changes in the structure of the amorphous MnO2 during charge/ discharge cycles of the zinc ion battery. Platelets identified as Zn4SO4(OH)6.5H2O are formed during discharge, which subsequently disappear during charging. This indicates that Zn2+/H+ could be reversibly associated with/ dissociated from the MnO2 electrode during cycling, accompanied by the formation/dissolution of Zn4SO4(OH) 6.5H2O.

January, February, and March 2023

This months’ images are taken from four different papers in the latest issues of JSST and once again highlight the breadth of sol-gel science and technology, together with the areas in which our community is making an impact.

The first series is taken from the work of Wang, Zou, Huang, Xu, Chen, Yan, Zhu, Cao and Lin entitled “Efficient prevention of cracking of external gelation-made thorium oxide microspheres by hydrothermal treatment” (JSST (2023) 105, 709-720; https://doi.org/10.1007/s10971-023-06046-5 (this opens in a new tab)). This work explores the effect of synthesis conditions on the structural evolution of relatively large, uniform ThO2 “microspheres” prepared via external gelation, for potential applications in nuclear fuel rods. The as-prepared spheres (top-left image) were prepared from a colloidal ThO2 solution containing PVA, using a vibrating needle to generate droplets which were subsequently gelled and aged in an ammonia solution. Hydrothermal treatment of the as-prepared spheres resulted in the product shown in the top-right image. Subsequent heat treatment of the as-prepared and hydrothermallyprocessed samples at elevated temperatures led to a cracked product in the former case, compared to high-quality, crack-free spheres in the latter case. The effect of hydrothermal treatment on the structure and composition of the spheres is elucidated.

The second series of micrographs is from the work of Patel and Joshi. This paper, entitled “Green and chemical approach for synthesis of Ag2O nanoparticles and their antimicrobial activity” (JSST, (2023) 105, 814-826; https://doi.org/10.1007/s10971-023-06036-7 (this opens in a new tab)), investigates different approaches for the synthesis of silver oxide nanoparticles and their associated antibacterial activity. The nanoparticles were synthesised by either (a) the dropwise addition of an extract obtained by boiling the leaves of the Salix Integra plant to a solution of AgNO3; or (b) addition of aqueous ammonia solution to a solution of AgNO3 followed by addition of citric acid. The latter synthesis yielded an intriguing fibrous aggregate structure, as shown in the micrograph on the right. At higher magnification, arrays of Ag2O nanoparticles are evident (see image on the left). Both samples exhibited antimicrobial activity towards M. tuberculosis H37Rv, M. fortuitum and M. chelonae, but were essentially inactive against M. abscessus.

The third series of images is from the work of Liu, Wang, Du, Song, Zhang, Li, and Chang entitled “Significantly boosting the visible light activity of BiOCl by facile solvothermal doping with chromium” (JSST, (2023) 105, 793-803; https://doi.org/10.1007/s10971-023-06047-4 (this opens in a new tab)). This paper explores the effect of doping BiOCl photocatalysts with metal ions such as Cr(III), Zn(II), Mn(II), Cu(II) and Ni(II), with the best results being obtained with Cr(III) doping. In the micrographs below, the images in the left-hand column illustrate the flowerlike structure of undoped BiOCl, while the other columns illustrate the effect of doping with 0.5 % (b,f), 5 % (c,g) and 10 % Cr(III) (d,h). The incorporation of Cr(III) within BiOCl significantly enhanced the photocatalytic activity of the material, with over 99 % of a model pollutant (rhodamine B) being decomposed within four minutes under the conditions used in the study. In contrast, only 60 % degradation was obtained in the case of the undoped catalysts under the same conditions.

The final series of images is from the work of Hashemi, Ataollahi, Hasani, and Seifoddini. This paper, entitled “Synthesis of the cobalt ferrite magnetic nanoparticles by sol–gel auto-combustion method in the presence of egg white (albumin)” ((JSST, (2023) 106, 23-36; https://doi.org/10.1007/s10971-023-06073-2 (this opens in a new tab)), describes the synthesis of cobalt ferrite nanoparticles, via auto-combustion, in the presence of varying quantities of egg white albumin. Such proteins are known to form stable complexes with metal ions in aqueous solution, and intriguing variations in the morphology (size and shape) of the CoFe2O4 particles are evident as the quantity of albumin in the precursor solutions is varied from 0 (micrograph (a)) to 0.25 (b), 0.5 (c) or 0.75 g (d). The results obtained indicated that the saturation magnetization and coercivity were significantly enhanced in samples processed with the albumin.

September, October, November, and December 2022

This months’ images are taken from four different papers in the latest issues of JSST and once again highlight the breadth of sol-gel science and technology, together with the areas in which our community is making an impact.

The first series is taken from the work of Ma, Liu, Du, Ge and Sun entitled “Pt nanoparticles anchored on bifunctional CuFe2O4 submicrospheres with improved catalytic properties for the reduction of [Fe(CN)6]3− by S2O32−” (JSST, (2022); https://doi.org/10.1007/s10971-022-05963-1 (this opens in a new tab)). This work explores the synthesis of catalytically active spherical CuFe2O4 cores with diameters of 200-300 nm, and the subsequent deposition of Pt nanoparticles to form core-shell CuFe2O4@Pt nanocomposite catalysts. Their results demonstrate that the intrinsic catalytic properties of the CuFe2O4 cores with respect to the reduction of [Fe(CN)6]3- to [Fe(CN)6]4- are significantly enhanced by the homogeneous dispersion of Pt nanoparticles immobilised on the surface of the cores.

The second series of micrographs is from the work of Deepthi, Sebastian and Vidhya. This paper, entitled “Influence of GO content on ZnO: GO composite thin films for visible light driven photocatalytic degradation of model pollutants” (JSST, (2022); https://doi.org/10.1007/s10971-022-05976-w (this opens in a new tab)), investigates the effect of graphene oxide (GO) content on the photocatalytic activity of ZnO:GO films for the decomposition of organics such as methylene blue and phenol. The resulting spin-coated films have an intriguing ripple-structured morphology, which is modulated by varying the GO content from 0 to 20 % (Images b (0 %); c (5 %); d (10 %); and e (20 %). The nanostructure varied across multiple photocatalytic cycles (compare image (d) (10 % GO,0 cycles); and image (f) (10 % GO, 5 cycles), although only minor reductions in the corresponding photocatalytic activity were observed. The film containing 10 % GO was found to be more efficient than the undoped ZnO by 89 % and 74 % for the degradation of methylene blue and phenol, respectively.

The third series of images is from the work of Yang, Pan, Fang, Su and Cheng entitled “Fabrication of Ce doped CoIn2S4 microspheres as efficient photocatalyst for degradation of rhodamine B” (JSST, (2022) 104, 380- 386; https://doi.org/10.1007/s10971-022-05945-3 (this opens in a new tab)). This paper explores the fabrication and characterisation of striking flowerlike particles composed of nanosized sheets doped with varying Ce content (image (a), CoIn2S2; images (b, c, d), Ce/CoIn2S2 with 5, 10 or 20 % Ce, respectively). Doping was found to enhance the photocatalytic activity of the nanomaterial, with the optimum performance obtained with 10 % doping.

The final series of images is from the work of Kazi, Tigote, Gaikwad, Kamble, Bhale, Shringare, Musrif and Inamdar. This paper, entitled “Effect of embedding aluminium and yttrium on the magneto-optic properties of lanthanum spinel ferrite nanoparticles synthesised for photocatalytic degradation of methyl red” ((JSST, (2022) 104, 354-364; https://doi.org/10.1007/s10971-022-05848-3 (this opens in a new tab)), describes the synthesis of a series of substituted ferrites with stoichiometry La1-xAlxYyFe2-yO4 and their photocatalytic activity for the decomposition of methyl red. The porous microstructure and crystallite size of the materials are modulated by the values of x and y, for x=y=0.25, 0.5 and 0.75 (Figures A, B, and C, respectively). The magnetic properties (magnetization, hysteresis and coercivity) are also controlled by the extent of doping. The highest photocatalytic activity for the degradation of methyl red was observed for x=y=0.75.

June, July, and August 2022

This months’ images are taken from four different papers in the latest issues of JSST and once again highlight the breadth of sol-gel science and technology, together with the areas in which our community is making an impact.

The first series is taken from the work of Fukatsu, Karim, Okada and Takahashi entitled “Alcohol-induced deboronation of organoborosilicate thin films” (JSST, (2022); https://doi.org/10.1007/s10971-022-05897-8 (this opens in a new tab)), which explores the post-synthesis modification of a photocurable organoborosilicate thin film. The AFM image on the left illustrates the surface morphology of the organoborosilicate film after photo-curing, which exhibits an intriguing morphology with a surface roughness (Ra) of 0.2 nm. Following treatment of the coating with methanol vapour for 30 minutes at room temperature, significant deboronation of the thin film occurred, yielding the coating illustrated on the right. The substantial increase in surface roughness (Ra = 0.4 nm) accompanying this treatment opens up interesting possibilities for creating new rigid frameworks for nanofabrication.

The second series of micrographs is from the work of Xu, Yu, Liu, Li, Li and Yang. This paper, entitled “Colorful patterned organic–inorganic hybrid silica films with a cholesteric structure” (JSST, (2022) 104: 91-96; https://doi.org/10.1007/s10971-022-05926-6 (this opens in a new tab)), explores the structural colours that can be obtained by modulating the composition of an organic/inorganic hybrid silica film incorporating an enantiotropic nematic phase and a chiral dopant. The optical micrographs in the top pane illustrate the effect of varying the fraction of chiral additive on the structural colours obtained, which vary from red to blue with increasing chiral-additive content. The corresponding changes in the morphologies of the coatings are illustrated via SEM for the 3.0 and 4.5 wt% materials in the bottom pane, with variations in the helical pitch from 447 to 293 nm being evident as the concentration of chiral additive was increased from 3.0 to 4.5 wt%.

The third series of images is from the work of Khoroshko, Borisenko, Baltrukovich, Nurmonov and Ruzimuradov entitled “One-step sol-gel fabrication of TiO2/(CuO+Cu2O) photocatalysts” (JSST, (2022); https://doi.org/10.1007/s10971-022-05906-w (this opens in a new tab)). This paper explores the fabrication of a striking whisker-like structure on copper foils, which is composed predominantly of CuO and TiO2, together with smaller quantities of Cu2O. Different morphologies were obtained for TiO2 coatings deposited on pre-oxidised (450 oC) (a) or unoxidized (b) copper foils, following post-deposition calcination of the coatings at 450 oC. The observed photocatalytic activity of the highly textured surfaces was attributed to efficient separation of photogenerated charge carriers at the TiO2/(CuO or Cu2O) heterojunctions.

The final series of images is from the work of Yang and Zhu. This paper, entitled “Synthesis and characterization of AlCl3-chitosan composite aerogels incorporating polyvinyl alcohol and bentonite clay” ((JSST, (2022); https://doi.org/10.1007/s10971-022-05848-3 (this opens in a new tab)), describes the synthesis of a series of aerogels containing varying quantities of bentonite. The left-hand images below illustrate the structure of aerogels obtained without added bentonite, while those on the right are for an aerogel containing a small quantity of bentonite. The addition of bentonite was found to decrease the density of the aerogels (from 0.129 to 0.094 g.cm-3 for the samples illustrated below) and increase their specific moduli (from 66 to 81 m2.s-2). The thermal conductivity was also decreased significantly by the addition of bentonite (from 55-65 to 45-50 mW.m-1 .K-1). The aerogels exhibited significantly enhanced fire retardancy compared to that of more conventional materials such as expanded polystyrene and polyurethane foams, indicating potential applications as thermal insulation and fire-retardant materials.

April and May 2022

This months’ images are taken from four different papers in the latest issues of JSST and once again highlight the breadth of sol-gel science and technology, together with the areas in which our community is making an impact.

The first series is taken from the work of Yamamoto, Shimoda, Sato, Nakaya, Ohshita and Gunji entitled “Preparation and film properties of polysiloxanes consisting of di- and quadra-functional hybrid units” (JSST, (2022); https://doi.org/10.1007/s10971-022-05806-z (this opens in a new tab)), which explores the mechanical properties of colourless, transparent gel films prepared from siloxane precursors containing both di- (D) and quadra-functional (Q) siloxane groups. Varying the arrangement of D and Q moieties within the precursor enabled the mechanical properties of the hybrids to be modulated, with Young’s modulus and fracture strengths of around 450 and 3.7 MPa being demonstrated.

The second series of micrographs is from the work of Chen, Tao, Shang, Ma, Li, Cao, Li, Li, Li, Xiao and Zhang. This paper, entitled “Rutile TiO2 nanorods grown on carbon nanotubes as high-performance lithium-ion batteries anode via one-dimensional electron pathways” (JSST, (2022); https://doi.org/10.1007/s10971-022-05835-8 (this opens in a new tab)), explores the properties of rutile nanorods grown on carbon nanotubes via a microwave-assisted hydrothermal method. The intriguing morphologies obtained, which are illustrated in the micrographs below, yielded an initial discharge capacity of 315 mAh.g-1 at 0.3 C when the materials were used as anodes in lithium ion batteries. This was substantially higher than the corresponding values obtained for physically mixed rutile and CNT or pure rutile. Excellent cycling performance was also demonstrated, with 93 % of the initial capacity retained at 1C after 200 cycles. The enhanced performance was attributed to the shorter electron-transfer distances via the onedimensional pathways established by the CNTs and TiO2 nanorods.

The third series of images is from the work of Muto, Amano, Tan, Yokoi, Kawamura and Matsuda entitled “Ordered arrays of electrostatically assembled SiO2–SiO2 composite particles by electrophoresis-induced stimulation” (JSST, (2022); https://doi.org/10.1007/s10971-022-05854-5 (this opens in a new tab)). This paper explores the formation of electrostatically-assembled SiO2-SiO2 composite particles from ensembles of monodisperse 200 nm and 16 µm particles. Composite particles consisting of a 16 µm SiO2 core decorated with the 200 nm SiO2 particles (left image) were initially assembled using polyelectrolyte adsorption to control the surface charge of the core and decorating particles. The assembly of these exquisite composites was subsequently achieved by applying controlled AC and DC electric fields to yield 2D hexagonal close-packed structures (right image) or an AC field coupled with gravitational sedimentation to generate ordered 3D hexagonal close-packed arrays.

The final series of images is from the work of Mimura, Hamao, Itasaka, Liu and Hamamoto. This paper, entitled “Hydrothermal synthesis of perovskite-type solid electrolyte nanoplate” ((JSST, (2022); https://doi.org/10.1007/s10971-022-05810-3 (this opens in a new tab)), describes the hydrothermal synthesis of perovskite nanoplates with stoichiometry (A,La) TiO3 (where A is either Li or Na). The phase purity of the nanoplates was modulated by the processing conditions employed, with a single-phase perovskite being obtained when NaOH was used as a mineraliser. The nanoplates had a thickness of around 10 nm and an average size of around 360 nm. Pellets fabricated from the nanoplatelets exhibited a conductivity of 3.8x10-6 S/cm following sintering at 1000 oC, which was an order of magnitude higher than the corresponding values obtained using commercial powders with a more conventional morphology.

January, February, and March 2022

This months’ images are taken from four different papers in the latest issues of JSST and once again highlight the breadth of sol-gel science and technology, together with the areas in which our community is making an impact.

The first series is taken from the work of Borovik, Oestreicher, Angelomé, Barja and Jobbágy entitled “Room temperature synthesis of lanthanum phosphates with controlled nanotexture as host for Ln(III) through the Epoxide Route” (JSST, (2022); https://doi.org/10.1007/s10971-022-05744-w (this opens in a new tab)), and explores the use of an epoxide route for synthesising Eu(III)-doped LaPO4 as a Rhabdophane (this opens in a new tab)phase at ambient temperature. The work demonstrates control of the size and shape of the LaPO4 particles by modulating the mixed solvent system used for their synthesis, with diverse particle shapes such as dumbbells, urchins and needles being obtained with sizes from < 200 nm to > 5 µm.

Read it here. (this opens in a new tab)

The second series of micrographs is from the work of Hamed, Ahmad, Hairom, Faridah, Mamat, Mohamed, Suriani, Soon, Fazli, Mokhtar and Shimomura. This paper, entitled “Photocatalytic degradation of methylene blue by flowerlike rutile-phase TiO2 film grown via hydrothermal method” (JSST, (2022); https://doi.org/10.1007/s10971-021-05691-y (this opens in a new tab)), explores the effect of processing conditions such as initial alkoxide concentration on the morphology of flower-like rutile structures obtained under hydrothermal conditions. An intriguing series of film morphologies were observed, varying from rods oriented vertically on the substrate to flower-like and cauliflower-like materials. The flower-like morphology obtained using an initial alkoxide concentration of 0.10 M exhibited the best performance for the photocatalytic degradation of methylene blue.

The third series of images is from the work of Sfez, De-Botton, Avnir and Wakshlak entitled “Sol–gel glazes - a safe glass and ceramics coloring approach” (JSST, (2022); https://doi.org/10.1007/s10971-021-05699-4 (this opens in a new tab)). This paper explores the use of organic colorants (approved for use with humans) entrapped within aluminosilicate hybrid matrices as replacements for the more toxic inorganic compounds typically used as pigments in glass and ceramic technology. Such an approach, which provides an artist’s palette consisting of thousands of colorants, reduces the energy required to produce glazed products and facilitates ready recyclability. The images on the left illustrate tiles glazed using this approach, under normal (left) and UV irradiation (second from left), while the images in the right-hand pane illustrate the artistic potential of such technology.

The final series of images is from the work of Colusso, Cicerchia, Rigon, Gomes and Martucci. This paper, entitled “Photoluminescence properties of silk–carbon quantum dots composites” ((JSST, (2022); https://doi.org/10.1007/s10971-022-05742-y (this opens in a new tab)), explores solution casting approaches for producing silk fibroin-carbon quantum dot composites deposited on polydimethylsiloxane substrates. The top row of images illustrates the effect of varying the quantum dot content on the transparency of the hybrid films, while the bottom row shows the luminescence of the samples under UV irradiation. The best combination of transparency and luminescence intensity is achieved for a quantum-dot loading of 0.5 wt%, with higher concentrations leading to aggregation of the quantum dots and associated scattering and quenching of the luminescence.

December 2021

This month’s images are taken from two different papers in the latest issue of JSST and once again highlight the breadth of sol-gel science and technology, together with the areas in which our community is making an impact.

(this opens in a new tab)

(this opens in a new tab)

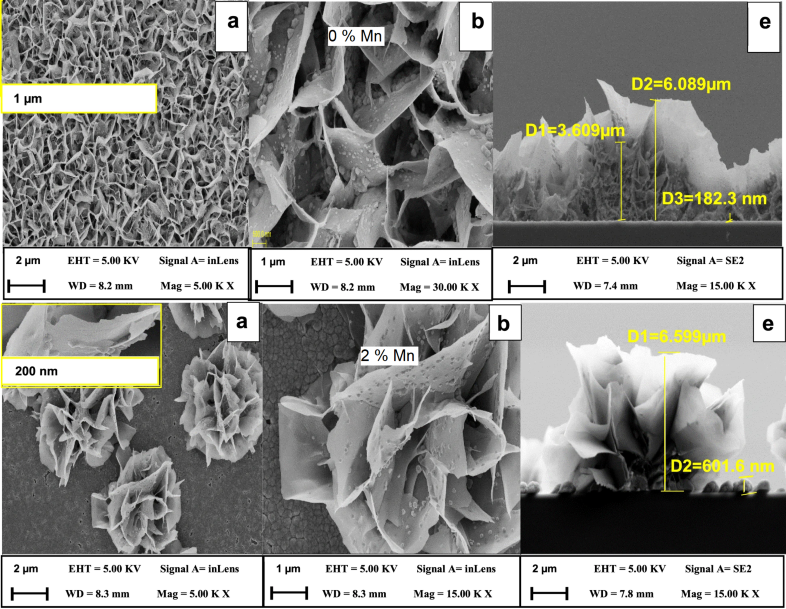

The first is taken from the work of AL-Jawad, Imran and Aboud entitled “Synthesis and characterization of Mn:CdS nanoflower thin films prepared by hydrothermal method for photocatalytic activity” (JSST, (2021), 100, 423-429; https://doi.org/10.1007/s10971-021-05656-1 (this opens in a new tab)), which explores the effect of Mn doping on the structural, morphological, optical and photocatalytic properties of nanoflowers produced by hydrothermal processing. The SEM micrographs illustrate the intriguing flower-like morphology of the materials, with increasing Mn doping leading to a decrease in the optical bandgap and increasing activity for the photocatalytic decomposition of dyes such as methyl blue and methyl violet.

The second micrograph is from the work of Hou, Chen, Zhao, Zou and Sun. This paper, entitled “Porous silica coated gold nanocages for chemophotothermal combined therapy” (JSST, (2021), 100, 562-570; https://doi.org/10.1007/s10971-021-05672-1 (this opens in a new tab)), explores the properties of drug-delivery systems based on gold nanocages entrapped within a porous silica shell, which is further coated with n-isopropylacrylamide to produce a material suitable for containing therapeutic drugs such doxorubicin. Under suitable light irradiation (808 nm), the gold nanoparticles absorb the NIR light and the resulting heat provides both a photothermal effect and swells the organic surface layer, thus releasing the encapsulated drug. The efficacy of the combined photothermal response and controlled drug delivery for destroying Hela cells in vitro is explored.

November 2021

This month’s images are taken from two different papers in the latest issue of JSST and once again highlight the breadth of sol-gel science and technology, together with the areas in which our community is making an impact.

The first is taken from the work of Ahmad, Abdullah, Yuhana, Yuliarto and Othman entitled “Enhanced photovoltaic performance of various temperature TiO2-SiO2-Ni-GO dye-sensitized solar cells assembled with PAN gel electrolyte” (JSST, (2021), https://doi.org/10.1007/s10971-021-05670-3 (this opens in a new tab)), which explores the effect of annealing temperature on the efficiency of dye-sensitized photovoltaic cells incorporating TiO2-SiO2-Ni-GO photoanodes. As shown in the micrographs, a highly porous, interconnected structure was obtained at 350 °C, which yields an efficiency of 3.4 % when used in conjunction with a solid gel electrolyte. In contrast, annealing at 400 or 450 °C leads to reduced efficiencies of 1.8 and 1.1 %, respectively.

The second series of micrographs is from the work of Dearden, Edwards, Evans, Woolsey, Blair, Harrison and Harrison. This paper, entitled “Synthesis of zinc oxide nanoplates and their use for hydrogen sulfide adsorption” (JSST, (2021), https://doi.org/10.1007/s10971-021-05686-9 (this opens in a new tab)), explores the sorption performance of ZnO nanoplates, nanoparticles and prisms for the uptake of hydrogen sulfide gas. Hydrogen sulfide reacts with ZnO via the formation of ZnS, with the nanoplates showing the highest uptake of 32 G S/100 g sorbent. The sorbents were readily regenerated by heating the sorbents at 600 °C

October 2021

This month’s images are taken from two different papers in the latest issue of JSST and once again highlight the breadth of sol-gel science and technology, together with the areas in which our community is making an impact.

The first is taken from the work of Atay and Gultepe entitled “The effect of spinning cycle on structural, optical, surface and photocatalytic properties of sol–gel derived ZnO films” (JSST, (2021), https://doi.org/10.1007/s10971-021-05661-4 (this opens in a new tab)), which explores the effect of the number of spinning cycles on the photocatalytic performance of ZnO films deposited by spin coating. It was found that the structural, optical and surface properties of the films was significantly modulated by increasing the number of layers deposited from three to five, due both to the formation of higher-surface-area arrays of nanosized particles aligned in columnar arrays and to a decrease in the number of defect states, leading to enhanced photocatalytic activity.

The second series of micrographs is from the work of Ramallo, Morrone, Lionello , Angelomé and Fuertes. This paper, entitled “Mechanical properties and structural integrity of devices based on sol–gel mesoporous oxides thin films” (JSST, (2021), https://doi.org/10.1007/s10971-021-05636-5 (this opens in a new tab)), explores the mechanical properties of porous and multi-layered titania/silica coatings and the process parameters that impact on their structural integrity. Nanoindentation studies demonstrated that mesoporous bilayer silica films exhibited a plastic behaviour without delamination during penetration throughout the entire film cross-section, while the bilayer titania coatings (with similar thickness) fractured and delaminated under such conditions. In the case of silica/titania and titania/ silica bilayer films, the failure during indentation was controlled by the properties of the more brittle titania layer. For example, in the case of the titania/silica coating, delamination of the top mesoporous silica layer is promoted by the stresses generated during failure of the titania layer.

September 2021

This month’s images are taken from two different papers in the latest issue of JSST and once again highlight the breadth of sol-gel science and technology, together with the areas in which our community is making an impact.

The first is taken from the work of Gegova-Dzhurkova, Nesheva, Dzhurkov, Šćepanović, GrujićBrojčin, Bineva, Mihailov, Levi, Manolov and Popović entitled “Modification of surface morphology and lattice order in nanocrystalline ZnO thin films prepared by spincoating sol–gel method” (JSST, (2021) 100, 55-67, https://doi.org/10.1007/s10971-021-05635-6 (this opens in a new tab)), which explores the effect of drying in a hot-air flow (90-95 oC) and laser annealing on key properties of the ZnO films, including internal stress, crystallinity and defect density. The optical micrographs at the top (with each micrograph displaying a viewing field ca. 50 μm in width) show the wrinkled morphology obtained in the absence of the hot-airdrying step (a) compared to the unwrinkled morphology obtained using an intermediate hot-air-drying step (b) to evaporate volatiles. An AFM image further illustrating the wrinkled morphology is also shown (c).

The second series of micrographs is from the work of Choudhary and Deepak. This paper, entitled “Investigation of time-dependent stability and surface defects in sol–gel derived IGZO and IZO thin films” (JSST, (2021), 100, 132-146, https://doi.org/10.1007/s10971-021-05615-w (this opens in a new tab)), explores the effect of gallium doping and ageing on the optical and electrical properties of indium gallium zinc oxide thin films deposited by spincoating. The as-processed films were typically uniform, transparent and amorphous when viewed under an optical microscope, with roughness below 2 nm. However, while they remained structurally and electrically stable with time, slight changes in morphology were evident after 13 days, with optical microscopy revealing some dark spots which were found to have high indium content. AFM studies of these defects revealed intriguing morphologies, with the effect being more evident in the absence of gallium doping.

August 2021

This month’s images are taken from three different papers in the latest issue of JSST and once again highlight the breadth of sol-gel science and technology, together with the areas in which our community is making an impact.

The first is taken from the work of Xiao, Wang, Liu, Wei, Luo, Zeng and Yi entitled “Promising pure gold aerogel: in situ preparation by composite sol–gel and application in catalytic removal of pollutants and SERS” (JSST, (2021) 99, 614-626, https://doi.org/10.1007/s10971-021-05597-9 (this opens in a new tab)), which describes the preparation of high-purity gold aerogels via reduction of Au(III) salts in the presence of a cellulose triacetate template. The as-prepared aerogels appear black in colour to the naked eye (consistent with highly dispersed, 10– to 15-nm-sized crystallites) and exhibit densities of 0.3-0.35 g.cm-3 (> 98 % porosity). Under Xe-lamp irradiation, they demonstrate good photocatalytic activity for the degradation of Congo red, 4-nitrophenol and rhodamine B. Following pressing at 1MPa, porous gold-coloured disks were obtained which were shown to be excellent substrates for acquiring surface-enhanced Raman spectra from rhodamine B solutions with concentrations as low as 10-7 M.

The second series of micrographs is from the work of Liu, Ma, Tao, Cui, Tian, Liu, He, Dong, Song and Zhang entitled “A facile approach to the synthesis of Er3+ –Yb3+ –Mo6+ co-doped TiO2/Yb2Ti2O7 electrospun nanofibers and high thermal sensitivity” (JSST, (2021), 99, 557-564, https://doi.org/10.1007/s10971-021-05598-8 (this opens in a new tab)). This paper describes the synthesis of luminescent nanofibers synthesised by electrospinning for potential applications in optical up-conversion. The SEM micrographs on the left show the structure of the fibres before (A-D) and after (E-H) annealing at 1000 oC for Er:Yb:Mo:Ti molar ratios of 0:0:0:100 (A,E); 1:10:2:100 (B,F); 2:20:4:100 (C,G); and 5:50:10:100 (D,H). The TEM EDX elemental maps for the latter system are included on the right.

The final series of micrographs is from the work of Güler, Selen, Başgöz, Safa and Yahia entitled “Adsorption properties and synthesis of silica aerogel-hollow silica microsphere hybrid (sandwich) structure” (JSST, (2021), https://doi.org/10.1007/s10971-021-05622-x (this opens in a new tab)), which explores the uptake of methylene blue on a hierarchical silica structure in which silica aerogels are supported on hollow silica microspheres. The use of the hollow microspheres to produce a “sandwich” structure enhances the mechanical strength of the adsorbent, thus facilitating its removal from solutions once the sorbent becomes saturated and its subsequent reuse. The SEM micrograph (20 nm scale bar) illustrate the morphology of the system after uptake of methylene blue, while the optical images illustrate the colour of the hybrid before and after uptake

July 2021

This month’s images were again taken from two different papers in the latest issue of JSST and once again highlight the breadth of sol-gel science and technology, together with the areas in which our community is making an impact.

The first is taken from the work of Chen, Qian, Sun, Song, Liu, and Lyu entitled “Grain size engineering and growth mechanism in hydrothermal synthesis of Bi0.5Na0.5TiO3 thin films on Nb-doped SrTiO3 substrates” (JSST, (2021), https://doi.org/10.1007/s10971-021-05586-y (this opens in a new tab)), which explores the effect of varying mineraliser concentrations on the morphology of epitaxially-grown thin films on single-crystal substrates. Decreasing the concentration of the mineraliser (NaOH) from 10 M (left-side image) to 6 M (right-side image) transforms the large rectangular, randomly-oriented grains (with an average size of 250 nm) into smaller rectangular grains (average size of 135 nm) which are more uniformly oriented on the substrate to yield a relatively flat surface. Such grain-size engineering provides a facile approach for optimising the energy-storage density and efficiency of devices such as thin-film capacitors

The second series of micrographs is from the work of Shen, Jiang, Li, Yang, Zhang, Zhang and Pan entitled “Hydrogen production by ethanol steam reforming over Ni-doped LaNixCo1−xO3−δ perovskites prepared by EDTAcitric acid sol–gel method” (JSST, (2021), https://doi.org/10.1007/s10971-021-05588-w (this opens in a new tab)). This paper describes the structure and morphology of the title perovskite nanocomposite catalysts and the effect of composition (x=0, 0.5, 0.9) and operating parameters (reforming temperature, H2O:EtOH) on the ethanol steam reforming efficiency for the production of hydrogen from an ethanol feed. The micrographs illustrate the intriguing morphology of the optimum composition (x=0.5) before (left) and after (right) reduction in H2.

June 2021

This month’s images were again taken from two different papers in the latest issue of JSST and once again highlight the breadth of sol-gel science and technology, together with the areas in which our community is making an impact.

The first is taken from the work of El-Shafey, El Din, Abdelazim, Mamdouh, Salah, El-Dek and Zaki entitled “Innovative biotemplates for the synthesis of ZnO nanoparticles with versatile morphologies” (JSST, (2021), https://doi.org/10.1007/s10971-021-05546-6 (this opens in a new tab)), which explores the effect of different biotemplates on the morphology of the ZnO particles obtained, and the photocatalytic activity of the resulting materials. The micrographs on the left illustrate the coral-like morphology of the materials obtained in the absence of biotemplate, while those on the right show the striking differences obtained using clove as a biotemplate (with all processing conditions other- wise comparable), where ZnO ribbons are obtained.

The second series of micrographs is from the work of Padilla-Hernández, Medina-Ramirez, Avila-Ortega, Barrón-Zambrano, Muñoz-Rodríguez, Carrera-Figueiras and Pérez-Padilla entitled “Synthesis of hybrid polymeric fibers of different functionalized alkoxysilane coupling agents obtained via sol-gel and electrospinning technique: effect on the morphology by addition of PVA” (JSST, (2021), https://doi.org/10.1007/s10971-021-05567-1 (this opens in a new tab)). This paper describes the effect of processing parameters on the formation of electrospun hy- brids produced from PVA/PDMS-OH mixtures incorporating different coupling agents. The upper micrograph shows the cross-linked fibres obtained from a 50:50 (v:v) mixture of PDMS and PVA, with 3- cyanopropyl(triethoxy)silane as coupling agent. The lower-left and -right images illustrate the corresponding branched fibres obtained from a 30:70 (v:v) mixture of PDMS and PVA, with 3-aminopropyl(triethoxy)silane as coupling agent. The lower-right image was obtained using a five-fold increase in electrospinning flow rate.

May 2021

This month’s images were again taken from two different papers in the latest issue of JSST and once again highlight the breadth of sol-gel science and technology, together with the areas in which our community is making an impact.

The first is taken from the work of Jia, Bi, Liu and Lyu entitled “Electronic structure, morphology-controlled syn-thesis, and luminescence properties of YF3:Eu3+” (JSST, (2021), 98, 497-507; https://doi.org/10.1007/s10971-021-05536-8 (this opens in a new tab)), which explores the effect of processing parameters on the photoluminescence of a series of Eu(III)-doped YF3 materials using both density functional theory and experimental studies. The micrographs illustrate the intriguing changes in morphology obtained for YF3:0.1Eu3+ by varying the RE3+:NaF mole ratio under hydro-thermal processing conditions (180 oC) from 1:2 (a), 1:3 (b) 1:4 (c) and 1:5 (d).

The second series of AFM micrographs is from the work of Yang, Qu, Feng, Wang and Feng entitled “Wrinkling surface of mono-layered thin film derived by using trifluoroacetate solution” (JSST, (2021), https://doi.org/10.1007/s10971-021-05547-5 (this opens in a new tab)). This paper describes the effect of synthesis conditions on the formation of films with an unusual wrinkled morphology. The wrinkled films were obtained by first depositing a monolayered thin film on a rigid substrate via spin-coating and then applying a rapid pyrolysis thermal profile. The AFM images illustrate variations in the wrinkling morphology over an 84 μm x 84 μm area with increasing film thickness.

April 2021

This month’s images were again taken from two different papers in the latest issue of JSST and once again highlight the breadth of sol-gel science and technology, together with the areas in which our community is making an impact.

The first is taken from the work of Khizir and Abbas entitled “Hydrothermal growth and controllable synthesis of flower-shaped TiO2 nanorods on FTO coated glass” (JSST, (2021), https://doi.org/10.1007/s10971-021-05531-z), which explores the effect of hydrothermal reaction temperature on the structural evolution of titania nanorods deposited on fluorine-doped tin oxide substrates. Optimisation of the hydrothermal processing conditions results in an intriguing structure in which a vertical array of titania nanorods form a flower-like morphology on the FTO substrate. The effect of the substrate on the evolving structure is also explored by substituting the FTO substrate with an indium tin oxide substrate, which resulted in substantial cracking of the deposited layer.

The second series of micrographs is from the work of Shaoqiang, Dong, Geng, Lin, Hua, Jun, Yi, Minxia, Yaohua and Wei entitled “The influence of grain size on the magnetic properties of Fe3O4 nanocrystals synthesized by solvothermal method” (JSST, (2021), 98, 422-429; https://doi.org/10.1007/s10971-018-4909-2). This paper describes the effect of synthesis conditions on the shape of superparamagnetic iron oxide nanoparticles prepared via a solvothermal approach. The shapes of the nanoparticles obtained ranged from irregular structures, triangles and quadrilaterals to hexagonal nanocrystals with increasing solvothermal reaction time. The samples prepared using the longest reaction time could be readily separated from solution using an applied magnetic field, while those obtained at shorter reaction times could not.

March 2021

This month’s images were again taken from two different papers in the latest issue of JSST and once again highlight the breadth of sol-gel science and technology, together with the areas in which our community is making an impact.

The first is taken from the work of Zhang, Wu, Yang, Sun and Zhang entitled “Preparation of SBA-15 mesoporous silica grafted with bissalicylaldehyde

Schiff base for uptake of Pb(II) and Cu(II) from water” (JSST, (2021), 98, 170-182; https://doi.org/10.1007/s10971-020-05455-0), which explores the uptake of Cu(II) and Pb(II) on SBA-15 decorated with bissalicylaldehyde Schiff base. Micrographs a, b and c illustrate the structure of the as-prepared SBA-15, while d, e and f demonstrate that the structure remains intact after functionalisation with the Schiff base. Micrographs g and h show the elemental maps of the functionalised SBA-15 after uptake of Pb(II) and Cu(II), respectively. The work confirmed that adsorption occurred on the functionalised monolayer, with good reuse and regeneration behaviour being observed.

The second series of micrographs is from the work of Cai, Liu, Li, Ni, Zhang, Gao and Jiang entitled “Facile fabrication of crystallized superhydrophobic hybrid coatings via solid-state hydrolysis/polycondensation of n-octadecyltrimethoxysilane” (JSST, (2021), 98, 271-279; https://doi.org/10.1007/s10971-021-05500-6). This paper describes ordered nanohybrid coatings incorporating aligned n-octadecyl chains that demonstrate superhydrophobicity.

The electron micrograph on the left illustrates the intriguing coral-like morphology of the coatings, while the optical micrographs on the right illustrate both the superhydrophobicity of the coatings and their self-cleaning properties.

February 2021

This month’s images were again taken from two different papers in the latest issue of JSST and once again highlight the breadth of sol-gel science and technology, together with the areas in which our community is making an impact.

The first is taken from the work of Zhan, Nie, Wu, Li, Ding, Ma and Chen entitled “Novel rare earth ions doped Bi2WO6/rGO hybrids assisted by ionic liquid with enhanced photocatalytic activity under natural sunlight”, (JSST, (2021), https://doi.org/10.1007/s10971-021-05494-1), which explores the effect of doping with various rare earth ions on the photocatalytic activity of Bi2WO6/graphene oxide hybrids prepared via sol-gel processing. The micrographs illustrate the intriguing morphology of the undoped Bi2WO6 (a, b), Bi2WO6/graphene oxide hybrids (c, d) and Er-doped-Bi2WO6/GO hybrids (e, f).

The second series of micrographs is from the work of Dong, Qian, Li, Tang, Xiang, Chun, Lu, Han, Xia and Hu entitled “Fabrication of superhydrophobic PET filter material with fluorinated SiO2 nanoparticles via simple sol–gel process” (JSST, (2021), https://doi.org/10.1007/s10971-021-05483-4). This paper describes the preparation of superhydrophobic coatings deposited on polyethylene glycol terephthalate (PET) membranes used to filter flue gases arising from the sintering of iron and steel. The coatings were prepared via sol-gel processing using a mixture of TEOS and perfluorodecyltriethoxysilane (PDFTES). As illustrated in the SEM micrographs, the pore structure of the PET membrane (a, b) was essentially unchanged following deposition of either TEOS (c, d) or TEOS/PDFTES (e, f) sol-gel layers, although the surface roughness was increased. The corresponding optical micrographs illustrate the significant increase in water contact angle achieved in the case of the TEOS/PDFTES coating (i, 163 o) compared to that of the TEOS coating (h, 0 o) and the uncoated PET membranes (g, 126 o).

January 2021

This month’s images were again taken from two different papers in the latest issue of JSST and once again highlight the breadth of sol-gel science and technology, together with the areas in which our community is making an impact.

The first is taken from the work of Salazar-Hernández, Puy-Alquiza, Miranda-Avilés, Salazar-Hernández, Mendoza-Miranda, Mocada-Sánchez and del Ángel-Soto entitled “Comparative study of TEOS-consolidants for adobe building conservation” (JSST, (2021), https://doi.org/10.1007/s10971-020-05461-2), which reports the use of sol-gel derived materials for the conservation of adobe buildings from the 17th and 18th centuries. The first series of SEM images illustrate the effect of four different sol-gel formulations on the microstructure of an adobe sample, while the second row demonstrates the impact of the treatments on the degradation of the adobe under standard test conditions. This illustrates the efficacy of such sol-gel treatments for preserving historical and culturally significant buildings.

The second series of micrographs is from the work of Yang, Zhang, Shao, Li, Li, Liu, Tao, and Liu entitled “Facile preparation of flexible polyacrylonitrile/BiOCl/BiOI nanofibers via SILAR method for effective floating photocatalysis” (JSST, (2021), https://doi.org/10.1007/s10971-020-05453-2). This paper describes the preparation of a floating photocatalyst in which successive layers of BiOCl/BiOI heterojunctions are deposited on self-supporting electrospun PAN nanofibre mats to produce highly active photocatalysts. The series of micrographs on the left show the structure of the PAN/BiOCl (top), PAN/BiOI (middle) and PAN/BiOCl/BiOI heterojunctions obtained via the SILAR process, while the TEM images on the right illustrate the structure of the photoactive heterojunction, together with the elemental maps illustrating the uniform distribution of elements in the material.

December 2020

This month’s images were again taken from two different papers in the latest issue of JSST and once again highlight the breadth of sol-gel science and technology, together with the areas in which our community is making an impact.

The first is taken from the work of Abdel-Khalek, Rayan, Askar, Maksoud and El-Bahnasawy entitled “Synthesis and characterization of SrFeO3-δ nanoparticles as antimicrobial agent” (JSST, (2020), https://doi.org/10.1007/s10971-020-05431-8). Apart from their promising antimicrobial activity for wastewater treatment, optical spectroscopic studies suggest that the nanoparticles have potential photocatalytic activity. In addition, thermal and magnetic studies provide evidence for the multiferroic nature of the materials.

The second series of micrographs is from the work of Ge, Li, Li and Zhao entitled “Fabrication of HAP/Ag/SSD ternary nanocomposite and its antibacterial properties” (JSST, (2020), https://doi.org/10.1007/s10971-020-05418-5). This paper investigates the sustained antibacterial properties of hydroxyapatite/silver/silver sulfadiazine ternary nanocomposite rods with a hierarchical structure. Mesporous HAP nanorods (a) were initially used as a substrate onto which silver nanoparticles were loaded (b). Silver sulfadiazine was then produced in situ on the surface of the HAP/Ag nanorods to produce HAP/Ag/SSD (c).

November 2020

This month’s images were again taken from two different papers in the latest issue of JSST and once again highlight the breadth of sol-gel science and technology, together with the areas in which our community is making an impact.

The first is taken from the work of Capeli et al. entitled “Effect of hydrothermal temperature on the antibacterial and photocatalytic activity of WO3 decorated with silver nanoparticles” (JSST, (2020), https://doi.org/10.1007/s10971- 020-05433-6). This paper investigates the effect of processing parameters on the catalytic and antimicrobial properties of hierarchical WO3.Ag synthesised at various temperatures (100, 150 and 200 oC). Materials synthesised at 150 or 200 oC exhibited the highest photocatalytic activity for the degradation of rhodamine, while those synthesised at 100 oC exhibited the highest antibacterial activity against various bacterial strains

The second series of micrographs is from the work of Al-Mousoi and Mohammed entitled “Engineered surface properties of MAPI using different antisolvents for hole transport layer-free perovskite solar cell (HTL-free PSC)” (JSST, 96, 659-668 (2020)), which investigates the effect of different solvents on the performance of perovskite- based solar cells. The micrographs illustrate the structure of perovskite layers deposited using (a) toluene, (b) diethyl ether or (c) chlorobenzene and subsequently annealed at 100 oC for 15 minutes.

October 2020

This month’s images were again taken from two different papers in the latest issue of JSST and once again highlight the breadth of sol-gel science and technology, together with the areas in which our community is making an impact.

The first is taken from the work of Giménez, Ybarra and Soler-Illia entitled “Preparation of mesoporous silica thin films at low temperature: a comparison of mild structure consolidation and template extraction procedures” (JSST, 96, 287-296 (2020)). This paper investigates the effect of different template removal strategies for maintaining the structure of mesoporous thin films at temperatures less than 130 oC. Conditions such as the duration of thermal treatment, pH of extraction media, etc, were systematically explored. Such mesoporous thin films have many potential applications, including sensors, drug encapsulation and delivery and even “electronic tongues”.

The second series of micrographs is from the work of Uzunbayir, Kartal, Can Doluel, Yurddaskal and Erol entitled “Development of α-Fe2O3/TiO2 3D hierarchical nanostructured photocatalysts through electrochemical anodization and sol–gel methods” (JSST, 96, 441-451 (2020)). The micrographs illustrate TiO2 nanotubes obtained via an electrochemical anodization approach using varying anodization times. The increasing height of the nanotubes with increasing anodization time (from 15 mins to 45 mins) is clearly evident. The paper explores their activity for the photocatalytic degradation of methylene blue.

September 2020

This month’s images were again taken from two different papers in the latest issue of JSST and have been chosen to highlight the breadth of sol-gel science and technology, together with the areas in which our community is making an impact.

The first is taken from the work of from the work of Ahemad and Yu entitled “Investigating the Mechamism of Uniform Ag@SiO2 Core-Shell Nanostructures Synthesis by a One-Pot Sol-Gel Method” (JSST, https://doi-org. ezproxy.uws.edu.au/10.1007/s10971-020-05392-y) and investigates the effect of processing parameters on the nanoparticles obtained. Such core-shell nanoparticles have a wide variety of potential applications in such diverse fields as sensing, SERS substrates, biomedicine, etc. The top row of micrographs illustrate the range of different nanoparticles that can be obtained, while the bottom row provides an elemental analysis of an individual Ag@SiO2 nanoparticle.

The second series of micrographs is from the work of Bajpai, Mili, Hashmi, Srivastava, Tilwari, Mohapatra and Verma entitled “Synthesis and Characterization of Advanced Hybrid Titanium Compounds/F-MWCNTs Nanocomposites and their Antibacterial Activities” (JSST, 96(1), 153-165 (2020)). This paper investigates the antibacterial activity of hybrid systems in which titania-based materials are conformally impregnated on carbon nanotubes. The micrographs illustrate hybrids prepared from titania nanoparticles (left) and nanoflowers (right)

August 2020

This month’s images were taken from two different papers in the Special Edition of JSST featuring work presented at the 20th International Sol-Gel Conference held in St Petersburg during August 2019, highlighting the rich diversity of the areas in which sol-gel science and technology is impacting.

The first is from the work of Drozdov, Prilepskii, Koltsova, Anastasova and Vinogradov entitled “Magnetic polyelectrolyte-based composites with dual anticoagulant and thrombolytic properties: towards optimal composition” (JSST, 95(3), 771-782 (2020)). The micrographs illustrate the structure and morphology of magnetite nanoparticles, together with their behaviour as a magnetic fluid, which are used to explore the concept of magnetic polyelectrolyte-based thrombolytics.

The second is from the work of Desponds, Banyasz, Montagnac, Andraud, Baldeck and Parola entitled “Microfabrication by two-photon lithography, and characterization, of SiO2/TiO2 based hybrid and ceramic microstructures” (JSST, 95(3), 733–745(2020)). In this work, the effect of precursor chemistry on the resolution achieved during 3D printing of sub-micron features in ceramic grids using a two-photon laser absorption process is investigated. The micrographs illustrate the effect of increasing the Ti:Si mole ratio in the precursor sol formulation from 0.4 to 1.

July 2020

This month's images were taken from the work of Shijiao Zhao, Rui Xu, Jingtao Ma, Xuping Lin, Xing Cheng, Xingyu Zhao, Shaochang Hao, and Changsheng Deng entitled "Preparation and microstructure characterization of crack-free zirconium nitride microspheres by internal gelation combined with two-step nitridation" (JSST, 95(2), 398-407 (2020)). The internal gelation method was used to produce zirconia gel micropheres, where were then nitrided at 1500-1600 °C under reducing conditions. The optical micrograph in image (a) illustrates the size uniformity of the gold-colored microspheres obtained, while the SEM micrograph in image (b) illustrates their crack-free surface structure. Images (c) and (d) further illustrate the microstructure of the product, with the crystal faceting evident in (d).